自1978年成立以来,MSE Filterpressen®已成为固液分离领域的优质压滤机制造商之一。 借助MSE Filterpressen® 的压滤机设备,客户可以获得适用于工业分离过程的经过充分验证的创新解决方案。 MSE Filterpressen®的固/液分离专家利用知识来设计和提供根据区域和应用要求量身定制的压滤机工厂解决方案。

MSE过滤板技术参数

Technical Data of the filter plates

Chamber filter plate Membrane filter plate

Format Standard sizes; 400, 470, 500, 630, 800, 915, 1000, 1067. 1200, 1300, 1450, 1470, 1500, 1500 x 2000 and 2000 x 2000 mm. These formats are available in open and closed versions. Larger and differently sized formats on request. Standard sizes: 400, 470, 500, 630, 800, 915, 1000, 1067. 1200, 1300, 1450, 1470, 1500, 1500 x 2000 and 2000 x 2000 mm. These formats are available in open and closed versions. Larger and differently sized formats on request.

Sludge inlet Standard inlets: central inlet, decentralized inlet, corner inlet Standard inlets: central inlet, decentralized inlet, corner inlet

Pressure Depending on the version, standard products are suitable for a maximum filtration pressure of 8 bar or 16 bar. Depending on the version, standard products are suitable for a maximum filtration pressure of 7 bar and a maximum squeezing pressure of 16 bar.

Temperature The maximum permissible filtration temperature depends, among other things, on the filtration pressure, the chemical composition of the slurry to be filtered, the cycle time and the choice of material. The maximum permissible filtration temperature depends, among other things, on the filtration pressure, the squeezing pressure, the chemical composition of the sludge to be filtered and the choice of material. In addition, the membrane can be cooled or heated during the filtration cycle.

Materials Chamber filter plates can be made of the following materials for specific applications:

●Polypropylene homopolymer 1 copolymer

●Polypropylene Homopolymer FDA1 Copolymer FDA

●Antistatic polypropylene

●PVDF

●Antistatic PVDF

Other materials on request Membrane filter plates can be made of the following materials for specific applications:

●Polypropylene homopolymer/ copolymer

●Polypropylene Homopolymer FDA1 Copolymer FDA

●Antistatic polypropylene

●PVDF

Antistatic PVDF

●Thermoplastic elastomers (membrane)

●EPDM (membrane)

●NBR (membrane)

●FKM (membrane)

For membrane filter plates, combinations of different materials for membrane carriers and membranes are possible.

Features + lowest price

+ good cake discharge

+ automatic plate shifting possible

+ easy handling

+ highly possible filtration pressure

- Cake thickness can not be changed

- Max. cake thickness 50mm

- Splitting wash not appropriate + shortest filtration, washing and dewatering time

+ most effective washing results

+ splitting wash possible

+ lowest dewatering costs

+ highest DM-Content

+ best cake discharge

+ flexible cake thickness

+ lowest energy input

- restrictions at high temperatures

- heavier use of the filter cloth

- special safety measures required

MSE过滤板介绍

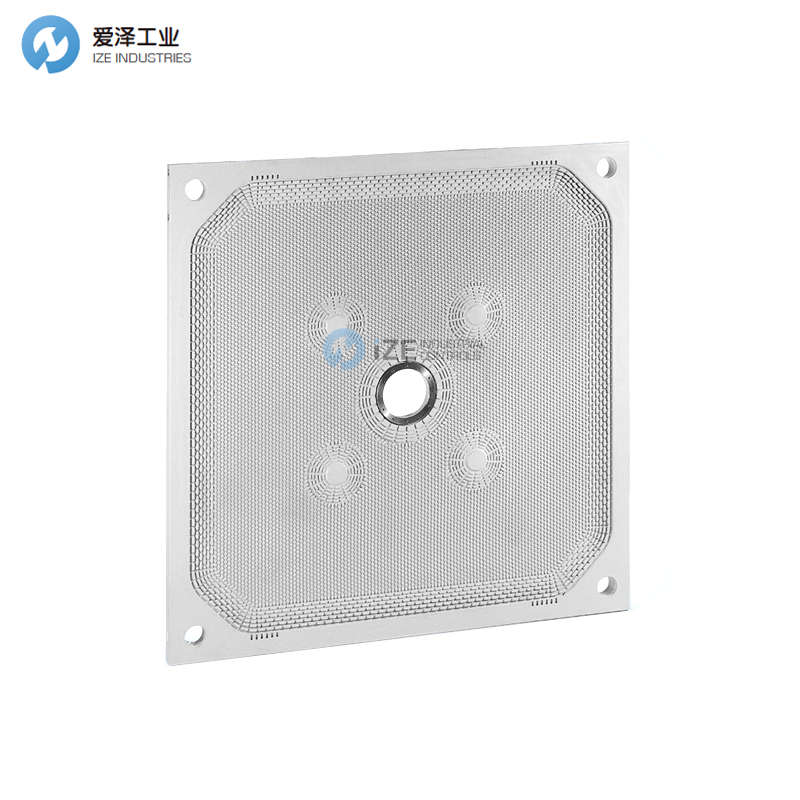

压滤机滤板

箱式压滤机和隔膜压滤机的滤板主要是由PP制成的耐化学腐蚀和耐压的塑料板。它们与悬垂的滤布一起构成了压滤机中滤饼过滤的处理区域,主要负责固液分离。还提供用于高达 +130°C 的高温和低至 -10°C 的低温的特殊材料,以实现连续运行。集成在过滤板中的排水表面设计有旋钮或凹槽。结果,滤布一方面得到支撑,另一方面滤液的限定流出是可能的。为您的个别应用选择过滤板的工艺工程参数是过滤表面、腔室深度或 滤饼强度和脱水程度。这导致腔室或滤饼体积和滤板类型。施工的基本方面取决于可选的工艺步骤,例如滤饼洗涤、滤饼干燥和吹芯等。

根据应用和领域,有不同渗透率、结构、设计(悬垂滤布、推入式滤布、CGR)和材料的滤布。

FILTER PLATES FOR FILTER PRESSES

Filter press plates for chamber filter presses and membrane filter presses are primarily chemically resistant and pressure-resistant plastic plates made of PP. Together with the overhanging filter cloth, these form the process space for cake filtration in the filter press and are mainly responsible for solid/liquid separation. Special materials for higher temperatures up to +130°C and for lower temperatures down to -10°C are also available for continuous operation. The drainage surface integrated in the filter press plates is designed with nubs or grooves. This supports the filter cloth on the one hand and allows the filtrate to flow off in a defined manner on the other. Process-technical parameters for the selection of a filter plate for your individual application are the filter area, the chamber depth or the filter cake thickness and the degree of dewatering. This results in the chamber or cake volume as well as the filter plate type.

Essential aspects of the design depend on the optional process steps such as filter cake washing, filter cake drying as well as core blowing and much more.

MSE过滤板其他常用型号:

MSE 800-KD25/TD/GK 33233673

MSE 800-KD25/TD/GK 33234673

MSE 800-GA4/KD25/TD/GK 33246027

MSE 33216135 Plate 800 KD25/TD/SWG

MSE 33216138 800KD25/TD/SG

MSE FILTERTUCH NEW + ORIGINAL+ ONE YEAR WARRANTY

爱泽工业成立于2010年,定位于向制造工业提供高端制造技术和设备。代理经营世界优质的电气自动化、机械与传动、流体控制、仪器仪表、工具等产品。作为电气,液压以及气动解决方案的合作伙伴,我们利用我们的全球协作团队,为客户提供先进解决方案,市场知识以及相关增值服务来帮助优化客户的工作效率,提高可靠性和安全性,致力于成为工业产品和解决方案的优质渠道。

如果有任何关于

MSE过滤板33216138 800KD25/TD/SG的疑问,请随时与我们沟通( )。我们将尽全力解决您的问题。

If you have any question for

MSE products, please feel free to dial 0086-21-3100 6702/ send request email to / browse our website:www.ize-industries.com.

MSE过滤板33216138 800KD25/TD/SG介绍

扫一扫,手机浏览

扫一扫,手机浏览